While the world changes, dairy cattle diets and challenges are also evolving for many. Several dairies have considered, or are actively, feeding unpasteurized milk back to the herd to avoid wasting valuable nutrients. For others, diets have changed in response to dwindling forage inventories.

These new ingredients, especially wet ones, being added to total mixed rations (TMRs) will heighten the need to manage potential risks from feed hygiene issues. Increased water activity in feed (due to rainfall, soaker lines/misters or adding water/milk to the diet) will raise the potential for microbial growth and feed spoilage.

Wild yeast is generally the first microbial contaminant to take hold in a spoiling TMR. Yeast are prevalent throughout the U.S., with humid and wet climates more prone to yeast challenges.

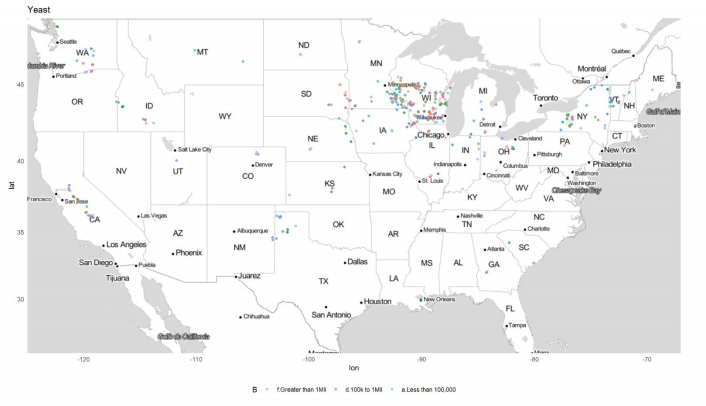

Matching global positioning system (GPS) coordinates to feed samples submitted to Rock River Labs via their FeedScan app helps us visualize where spoilage yeast contaminations are occurring relative to their geographic location.

Across the U.S. (see Figure 1), the red dots correspond to samples with more than 1 million colony-forming units (cfu) per gram of feed or TMR. For reference, grab the top knuckle on your pinky finger. This represents about one (1) gram of feed volume. Now think about 1 million yeast colonies on your top pinky knuckle! As depicted in Figure 1, there are already clear “hot spots” for yeast levels throughout the U.S. Add to this that spoilage yeast are only beginning to show their effects as many feeds harvested last fall were cold or frozen. These wet or delayed crops may have had some level of wild yeast present but have been under refrigeration up to now.

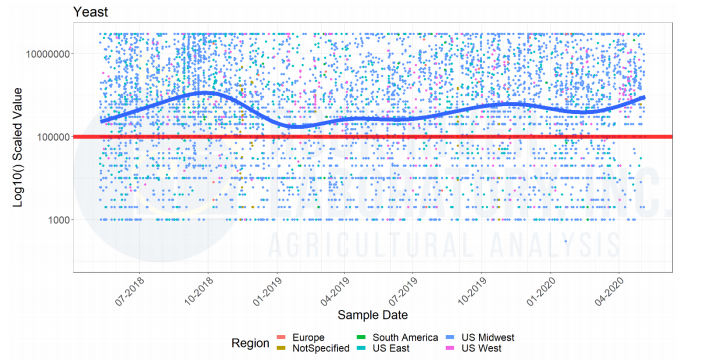

Additionally, Figure 2 shows that yeast counts are coming through at substantially higher levels than a year ago. With both the regional and temporal trends in mind, consider paying close attention to feed and TMR heating in the coming weeks and months.

Figure 1: Total yeast count results (colony forming units/g) for all feeds and TMR submitted to Rock River Laboratory in the past six months.

Figure 2: Total yeast count results (colony forming units/g) for all feeds and TMR submitted to Rock River Laboratory in the past two years.

While yeasts are likely to be a culprit for decreased TMR stabilities this year, keep in mind that other factors can contribute to this issue. Microbial contaminants, be it fungal (molds) or bacterial can also contaminate feeds either directly or by the compounds they produce such as alcohols, biogenic amines, and toxins. Pathogenic bacteria or fungi can colonize in the digestive tract, harming dairy cattle. On top of that, toxins can exert effects on the immune and reproductive systems, damage gut mucous and villi layers, and can disrupt rumen function. All of these factors can negatively affect cattle health and performance.

So what can you do to help manage your way forward this year?

A simple, cheap and timely way to screen for feed quality issues is to check feed bunk temperatures. Any temperatures 10°F or more above ambient temperature point to microbial growth and spoilage. This can be done using a digital thermometer, infrared thermometer or infrared camera. Be sure to take the temperature a few inches under the surface and not just the outer layer which doesn’t provide the full picture.

Monitor bunk temperatures several times per week if you are feeding milk back to your herd, adding water, feeding pushouts or bringing in wet commodity feeds.

Another simple, cheap and timely way is to listen to the cows. Many of the byproducts of feed spoilage, especially alcohols and biogenic amines, can cause cattle to back off feed intake volume and consistency leading to potential digestive upsets and inconsistent manure.

If you find your forage or TMR is heating or if intakes are waning while digestive upsets are up, consider adding Profresh Plus to the diet. For additional help in pinpointing the root cause of your feed quality challenges, reach out to your McNess representative. We offer a comprehensive Diet Challenge Assessment Tool which in turn enables us to recommend the optimal path forward.

Special thanks to Dr. John Goeser and Rock River Laboratory for content and assistance in producing this information.

Learn more about the McNess solutions by going to mcness.com/dairy-products/#feed-and-forage